A highly functional dish rack sold around the world

Product Design

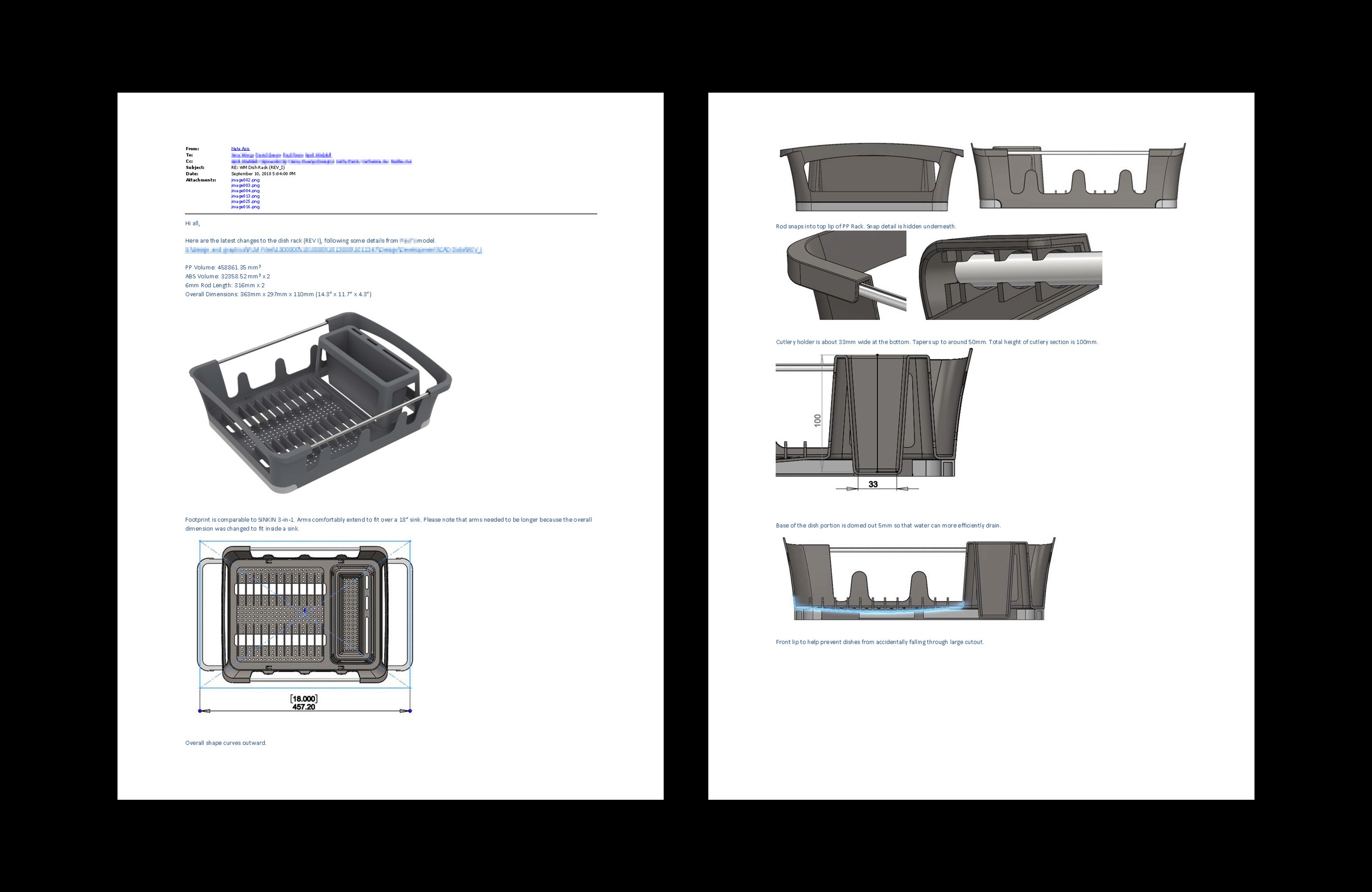

Injection molded plastic dish rack that can be used on a countertop, in the sink, or over the sink. A high-capacity, high-function dishrack with integrated utensil caddy, cup holders, and knife slots.

This project was limited to a very sharp cost, and had to provide a lot of function for the volume of plastic. Walmart had asked for an opening price point dish rack to add to their existing catalog of plastic dish racks. This dish rack had to add more features in order for it to fare well against competitors.

Communication with the Product Development team in Shenzhen was crucial early in the process. Design Engineering provided feedback on areas to address in the model for strength and advised on ways to reduce cost.

Early concepts were FEA tested by an external engineering company. Ultimately, their process did not work with the Umbra design team workflow. I took this as an opportunity to learn and apply the FEA tools in Fusion 360 in order to quickly validate

and iterate concepts. Over 20 iterative stress studies were conducted in order to best understand how the dishrack would behave under a full load of dishes when extended over a sink. The final model is representative of the best solution as learned from the FEA studies.

The final product was manufactured by Umbra as private label and sold to Walmart USA with an initial order worth over $125,000. Since then, Brigit dish rack can be found in retailers around the world.

Project details

Client

Walmart

Year

2019

Services

Industrial Design, Product Development